Screen Printing Solutions by DROP AG

Screen Printing Prepress Technology Built for Precision and Reliability

Screen printing demands accuracy, repeatability, and reliability at every stage of the workflow. DROP AG develops advanced prepress and imaging solutions that help professional screen printers achieve consistent, high-quality results — from fine details to long production runs.

What Is Screen Printing?

Screen printing is a versatile printing process where ink is transferred through a screen onto a substrate using a stencil. It is widely used in graphic, industrial, and specialty printing applications that require durability, opacity, and precision. The quality of screen printing largely depends on accurate and reliable screen preparation.

Flat screen printing is commonly used for applications that require high ink thickness and precise image reproduction. It is ideal for industrial graphics, electronics, glass, and decorative printing. Consistent exposure quality and accurate imaging are essential to achieve sharp details and repeatable results in flat screen production.

Rotary screen printing is designed for high-speed, continuous printing processes. It is widely applied in textile, packaging, and industrial printing, where efficiency and stability are critical. High-resolution imaging and reliable plate production ensure uniform print quality throughout long production runs.

Why DROP AG for Screen Printing

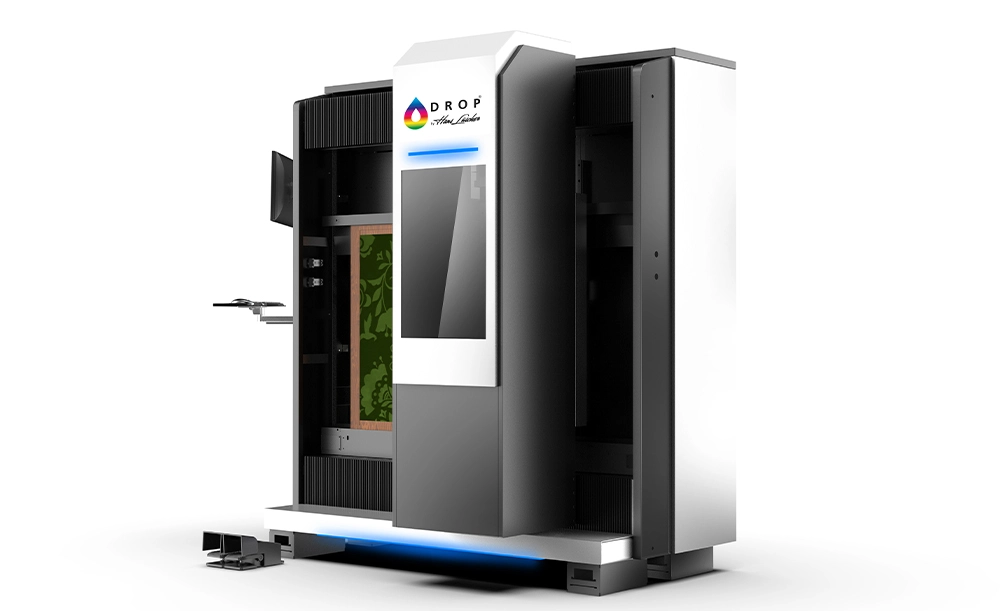

DROP AG offers a future-proof solution for both Flat Screen Printing and Rotary Screen Printing with the Phoenix DLES UV laser direct beamer.

The Phoenix DLES enables the production of high-quality printing plates for virtually all classic and industrial screen printing applications, combining efficiency, precision, and long-term reliability.

Key advantages:

- High-resolution UV laser imaging using a unique Longlife UV laser and high-resolution DMD chip with 4° exposure technology.

- Flexible optical resolutions: 1270 dpi for 133 LPI raster, 2540 dpi for fine curves and FM raster points, with additional options up to 25,400 dpi.

- Multiple high-energy UV lasers (375 nm / 405 nm) for curing high EOM and diazo emulsions.

- Advanced PDF segmentation algorithm supporting up to 12,700 dpi, ensuring smooth curves, sharp details, and accurate vector reproduction — ideal for precision industries such as TP and FPC.

- Intelligent stretch and shrink compensation (AI Scanner – optional) that automatically measures material deformation and adjusts TIFF files for highly accurate results, reducing manual work and errors.

Talk to Us About Screen Printing

Looking to modernize your screen printing prepress workflow or replace film-based processes?

Contact DROP AG to learn how our screen printing solutions can support your production requirements.